-

14" Kevlar® Terry High Heat Gloves 234-KT

Regular price $79.99 USDRegular priceUnit price / per -

18" V-Bit Jaw Tongs For Forging & Metal Working

Regular price $49.37 USDRegular priceUnit price / per -

23" Kevlar® Terry High Heat Glove 243-KT

Regular price $99.98 USDRegular priceUnit price / per -

Knights Precision Tool Wrap 100' Type 309 Stainless Steel Tool Wrap 100' x 40" x .002 Foil Wrap

Regular price $879.98 USDRegular priceUnit price / per$2,598.99 USDSale price $879.98 USDSale -

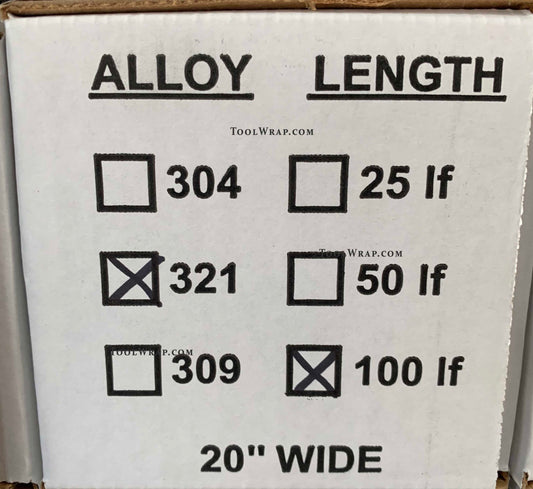

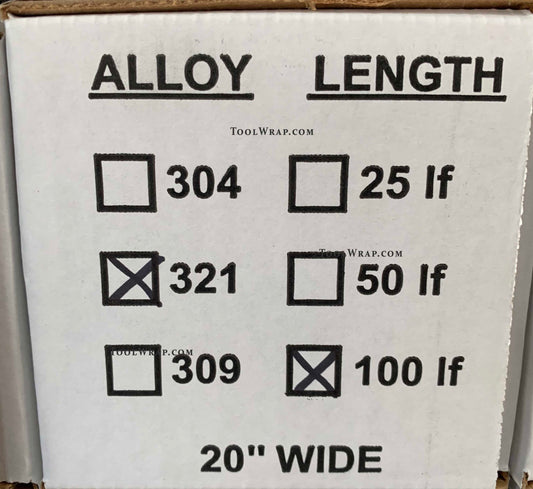

Knights Precision Tool Wrap 100' Type 321 Stainless Steel Tool Wrap 100' x 20" x .002 Foil Wrap

Regular price $327.88 USDRegular priceUnit price / per$629.00 USDSale price $327.88 USDSale -

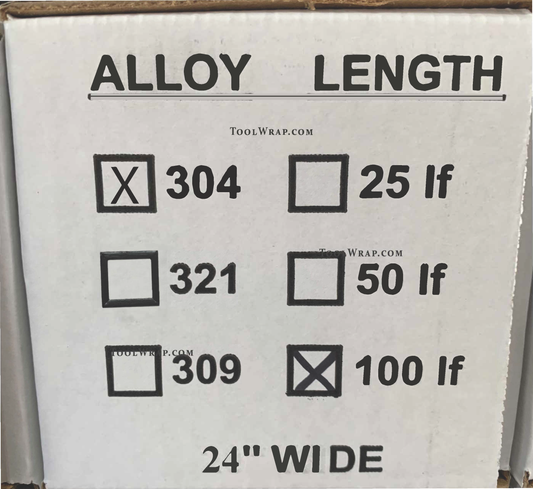

Knights Precision Tool Wrap 100' Type 304 Annealed Stainless Steel Tool Wrap 100' x 24" x .002 Foil Wrap

Regular price $289.85 USDRegular priceUnit price / per$724.35 USDSale price $289.85 USDSold out -

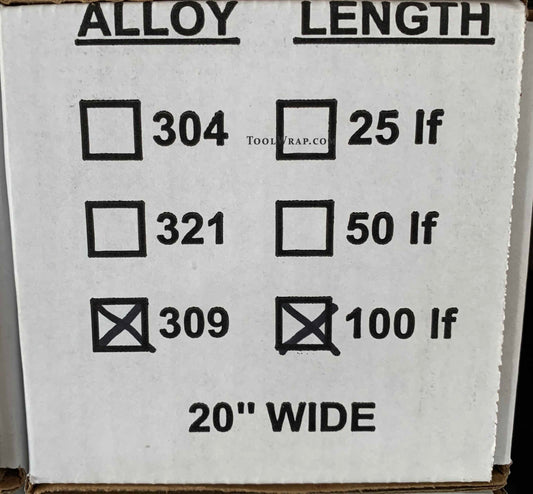

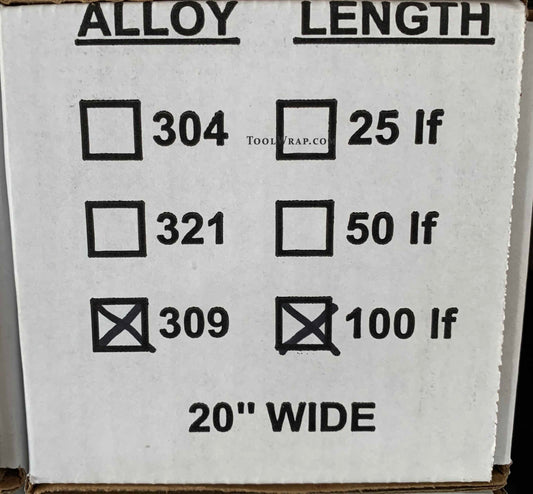

Knights Precision Tool Wrap 100' Type 309 Stainless Steel Tool Wrap 100' x 20" x .002 Foil Wrap

Regular price $387.88 USDRegular priceUnit price / per$799.00 USDSale price $387.88 USDSale -

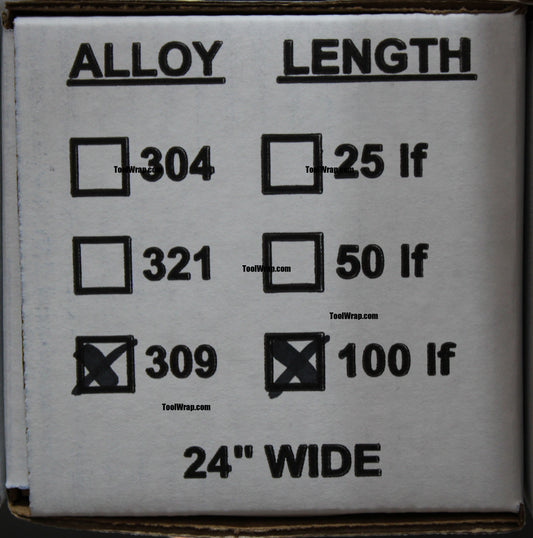

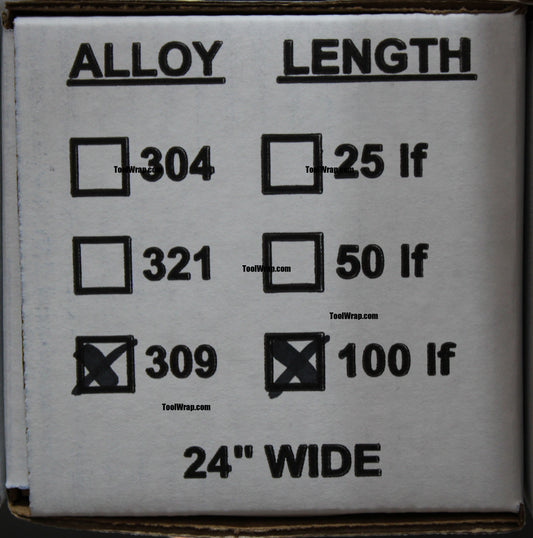

Knights Precision Tool Wrap 100' Type 309 Stainless Steel Tool Wrap 100' x 24" x .002 Foil Wrap

Regular price $589.80 USDRegular priceUnit price / per$1,100.00 USDSale price $589.80 USDSold out -

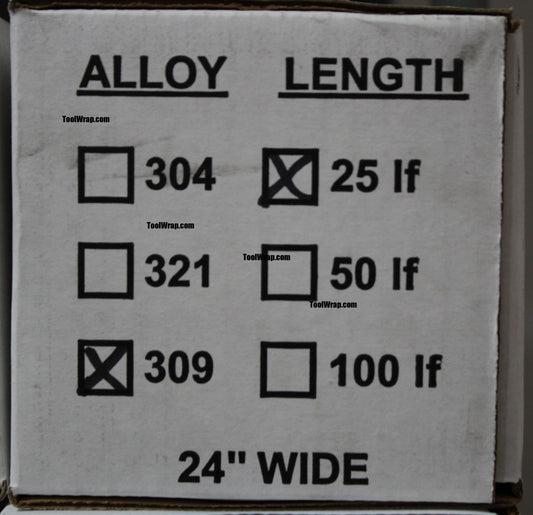

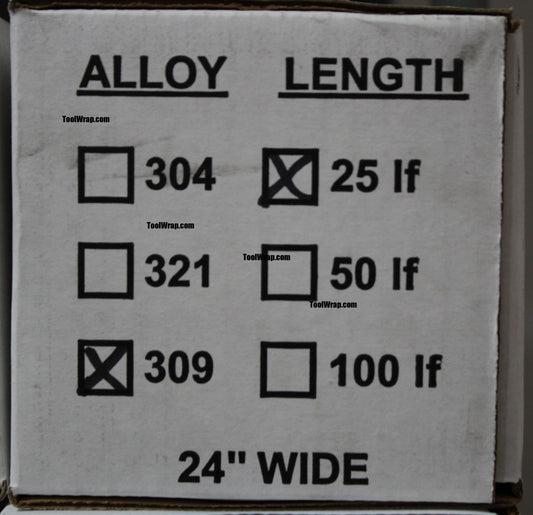

Knights Precision Tool Wrap 25' Type 309 Stainless Steel Tool Wrap 25' x 24" x .002 Foil Wrap

Regular price $149.99 USDRegular priceUnit price / per$269.99 USDSale price $149.99 USDSold out -

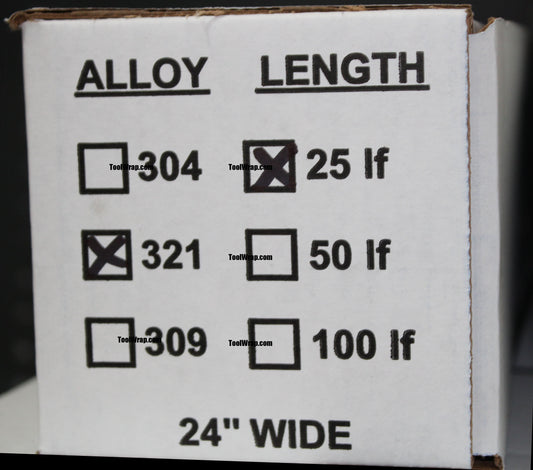

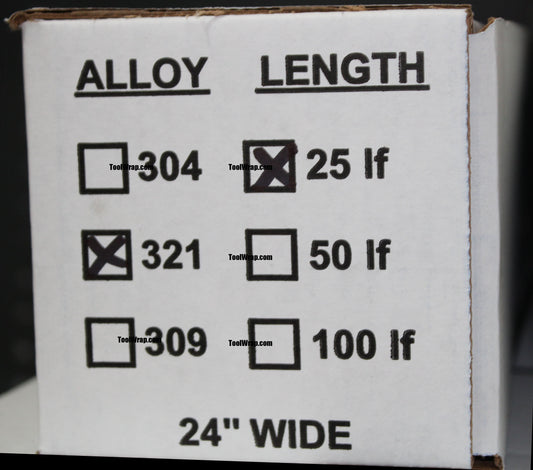

Knights Precision Tool Wrap 25' Type 321 Stainless Steel Tool Wrap 25' x 24" x .002 Foil Wrap

Regular price $189.99 USDRegular priceUnit price / per$289.90 USDSale price $189.99 USDSold out -

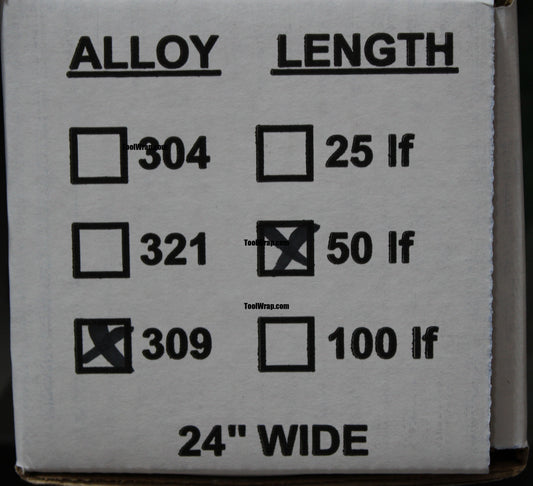

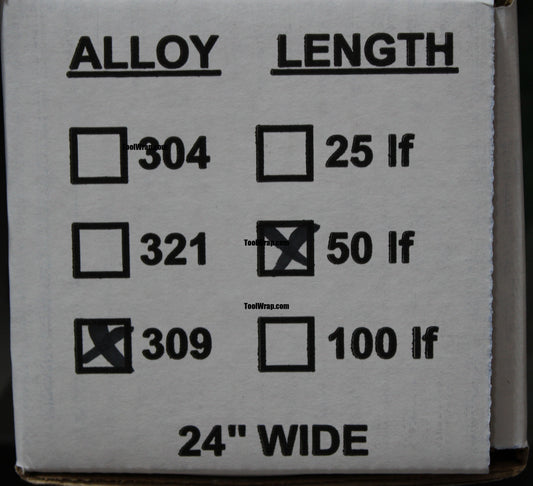

Knights Precision Tool Wrap 50' Type 309 Stainless Steel Tool Wrap 50' x 24" x .002 Foil Wrap

Regular price $379.80 USDRegular priceUnit price / per$899.00 USDSale price $379.80 USDSold out -

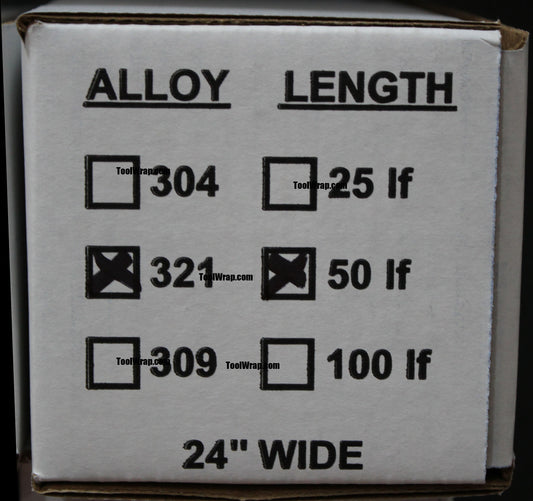

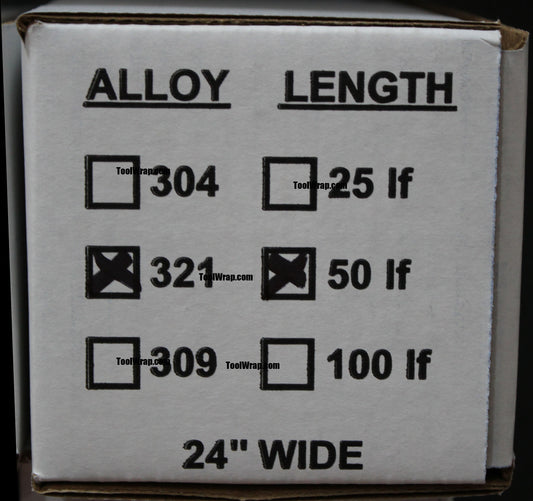

Knights Precision Tool Wrap 50' Type 321 Stainless Steel Tool Wrap 50' x 24" x .002 Foil Wrap

Regular price $199.88 USDRegular priceUnit price / per$429.99 USDSale price $199.88 USDSold out